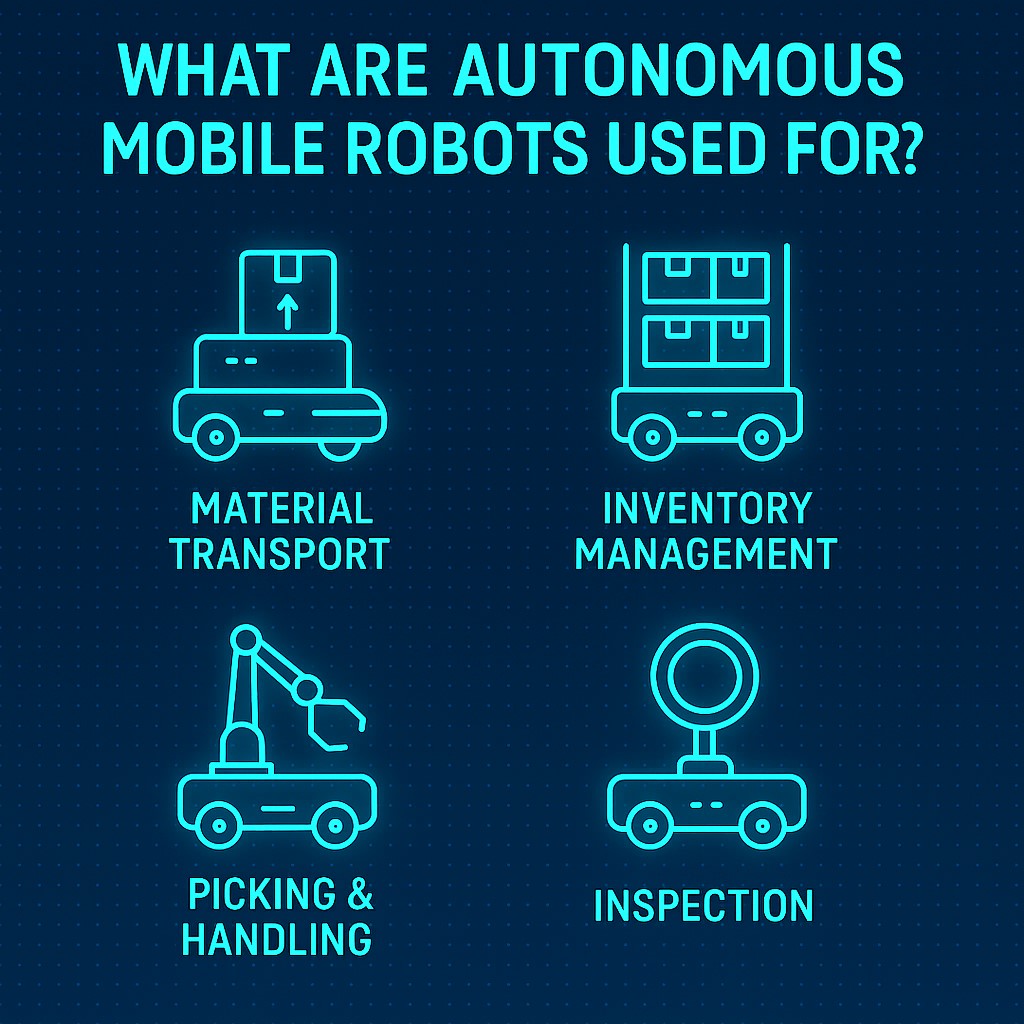

What Are Autonomous Mobile Robots Used For ?

Autonomous Mobile Robots (AMRs) are transforming industries by bringing smart mobility, adaptability, and efficiency to logistics, manufacturing, healthcare, and beyond. Unlike traditional automated guided vehicles (AGVs) that follow fixed paths, AMRs use sensors, artificial intelligence, and onboard computing to navigate dynamic environments on their own. But what exactly are they used for?

Let’s dive into the most practical and growing applications of AMRs across multiple sectors and how they are reshaping the modern workplace.

Material Handling and Transport

Efficient Movement of Goods

One of the most common uses of AMRs is in material handling. These robots can transport raw materials, components, or finished goods across facilities without human intervention. Their ability to avoid obstacles and dynamically reroute makes them ideal for complex factory or warehouse layouts.

For example, an AMR might pick up a load of components from the receiving dock and deliver it to a workstation. After assembly, another AMR can move the finished product to the shipping area. This reduces the need for forklifts, carts, or manual labor.

Reducing Downtime and Injuries

AMRs help streamline internal logistics by running repetitive transport tasks continuously. They reduce workplace injuries related to lifting or pushing heavy loads and allow human workers to focus on value-adding activities like quality control or assembly.

Inventory Management and Stock Replenishment

Real-Time Stock Updates

In warehouse operations, keeping accurate inventory counts is essential. AMRs integrated with barcode scanners or RFID readers can roam through storage aisles to monitor inventory levels. They provide real-time updates and alerts when stock levels are low or misplaced.

This real-time visibility reduces stockouts, overstocking, and manual counting errors.

Optimizing Shelf Restocking

In retail or warehouse environments, AMRs can identify empty shelves and autonomously deliver stock from storage areas to fill them. This not only improves efficiency but also ensures product availability on the floor without human delay.

Picking and Order Fulfillment

Smart Picking Systems

In e-commerce and distribution centers, AMRs assist in picking orders by guiding human pickers or autonomously retrieving bins from shelving systems. Some AMRs are equipped with robotic arms to directly pick and place items, reducing the need for human involvement altogether.

This significantly cuts down the time required to fulfill each order while improving accuracy and reducing human fatigue.

High Throughput and Scalability

Because AMRs can be easily scaled—just add more units—they’re an ideal solution during high-demand periods like holiday seasons. Unlike static conveyor systems, AMRs can operate flexibly across different zones.

Inspection and Monitoring Tasks

Facility Surveillance and Safety Checks

AMRs are used for inspecting equipment, environmental conditions, and operational status. Equipped with cameras and sensors, they can perform tasks like thermal scanning, gas detection, and floor monitoring in hazardous areas.

In environments like chemical plants or power facilities, AMRs can ensure safety without putting humans at risk.

Quality Control and Maintenance Alerts

In manufacturing, AMRs can be used to inspect production lines and detect anomalies. If an issue is found, the AMR can notify the maintenance team or even carry parts for repair to the necessary location, speeding up response time and minimizing downtime.

Support in Healthcare Facilities

Hospital Logistics

AMRs are increasingly used in hospitals to carry medication, linens, lab samples, and surgical tools between departments. These robots reduce the workload on nurses and support staff, allowing them to focus more on patient care.

Hospitals benefit from reduced cross-contamination risks and more efficient use of medical personnel.

Sanitation and Disinfection

Some AMRs are equipped with UV lights or chemical spray systems to sanitize hospital rooms or public spaces autonomously. Especially post-pandemic, this application has grown as a proactive infection control strategy.

Manufacturing Automation

Line-Side Delivery

In manufacturing, particularly in industries that follow just-in-time production, AMRs are used to deliver components directly to assembly lines. These robots synchronize with production schedules and reduce bottlenecks by ensuring that every workstation has the parts it needs.

Intra-Plant Logistics

AMRs play a key role in moving items from one part of the plant to another—whether it’s raw materials, subassemblies, or finished products. By automating this flow, manufacturers can increase throughput while maintaining flexibility.

Agriculture and Farming

Precision Agriculture

Autonomous mobile robots are now used in farming for tasks such as soil analysis, planting, and crop monitoring. These robots can map the field, identify areas that need attention, and carry out targeted interventions—saving resources and boosting yield.

Harvesting and Sorting

Some AMRs are designed to pick fruit or vegetables and sort them based on ripeness or size. This speeds up the harvest and reduces post-harvest labor costs.

Hospitality and Service Industry

Guest Assistance

In hotels and restaurants, AMRs act as delivery robots—bringing food, drinks, towels, or toiletries directly to guests. They are often equipped with touchscreen interfaces, allowing guests to place requests and receive items in minutes.

Cleaning and Floor Maintenance

Hotels and airports use AMRs for vacuuming, sweeping, or mopping floors autonomously. These robots improve cleanliness standards while operating without supervision, even during off-hours.

Construction and Mining

Site Monitoring

In construction zones, AMRs with LiDAR and GPS systems can navigate rough terrain and scan progress. They can deliver tools, materials, and even provide 3D scans of the worksite for real-time updates.

Underground and Hazardous Tasks

In mining operations, AMRs reduce the risk to human workers by exploring unstable or toxic areas, transporting samples, or assisting with ore extraction. They offer a safer and more efficient way to operate in extreme conditions.

Benefits of Using Autonomous Mobile Robots

Labor Cost Reduction

By taking over repetitive or dangerous tasks, AMRs allow businesses to operate with fewer human resources. This is especially useful during labor shortages or for 24/7 operations.

Improved Flexibility

Unlike traditional robots or AGVs, AMRs don’t need fixed routes or floor modifications. They adjust routes in real-time, making them suitable for dynamic environments.

Scalable and Customizable

From small startups to global enterprises, AMRs can be deployed and scaled as needed. Their modularity allows companies to tailor them for specific tasks or industries.

Future Outlook for AMRs

As AMRs continue to evolve with advances in AI, edge computing, and battery efficiency, their use cases will expand even further. They will likely become more collaborative, able to work safely side-by-side with humans in mixed environments. With lower costs and better performance, AMRs are set to become an integral part of the modern smart workforce.

Conclusion

So, what are autonomous mobile robots used for? The answer spans a wide range of industries—logistics, manufacturing, healthcare, hospitality, agriculture, and beyond. Whether it’s transporting goods, managing inventory, inspecting machinery, or assisting patients, AMRs are reshaping the way businesses operate. They offer a blend of intelligence, flexibility, and efficiency that’s unmatched by older automation systems.

As businesses strive to improve productivity and safety while reducing operational costs, autonomous mobile robots stand out as a smart and scalable solution.

✅ Key Takeaways

-

Autonomous Mobile Robots (AMRs) are smart, self-navigating machines designed to move and perform tasks without human intervention.

-

Material transport and logistics is the most common application, helping industries move items efficiently across warehouses and factories.

-

Inventory management is streamlined with AMRs performing real-time scanning, shelf stocking, and stock level monitoring.

-

Order picking and fulfillment are accelerated in e-commerce with AMRs either guiding humans or performing autonomous item retrieval.

-

Inspection and maintenance tasks are made safer and faster using AMRs for equipment checks, safety inspections, and anomaly detection.

-

Healthcare facilities use AMRs to transport medical supplies, disinfect rooms, and support staff with non-clinical tasks.

-

Manufacturing plants benefit from AMRs by using them for line-side delivery, intra-plant logistics, and just-in-time material supply.

-

Agriculture uses AMRs for crop monitoring, planting, and automated harvesting, boosting efficiency and yield.

-

Service industries like hospitality and retail adopt AMRs for guest service, food delivery, and autonomous floor cleaning.

-

Construction and mining rely on AMRs for site mapping, underground exploration, and transporting materials in hazardous zones.

-

AMRs reduce labor costs, increase operational flexibility, and are easily scalable to match business growth or seasonal demand.

-

Their AI-powered navigation allows them to operate in dynamic, unpredictable environments, unlike older AGV systems.

-

With ongoing innovation, AMRs are set to become essential in building future-ready, automated workplaces across industries.

Reference

https://en.wikipedia.org/wiki/Autonomous_robot

Link License – https://en.wikipedia.org/wiki/Wikipedia:Text_of_the_Creative_Commons_Attribution-ShareAlike_4.0_International_License

Dear Friends, welcome you to discover more technology content via my site. Kindly visit link below.

https://techsavvo.com/category/blog/