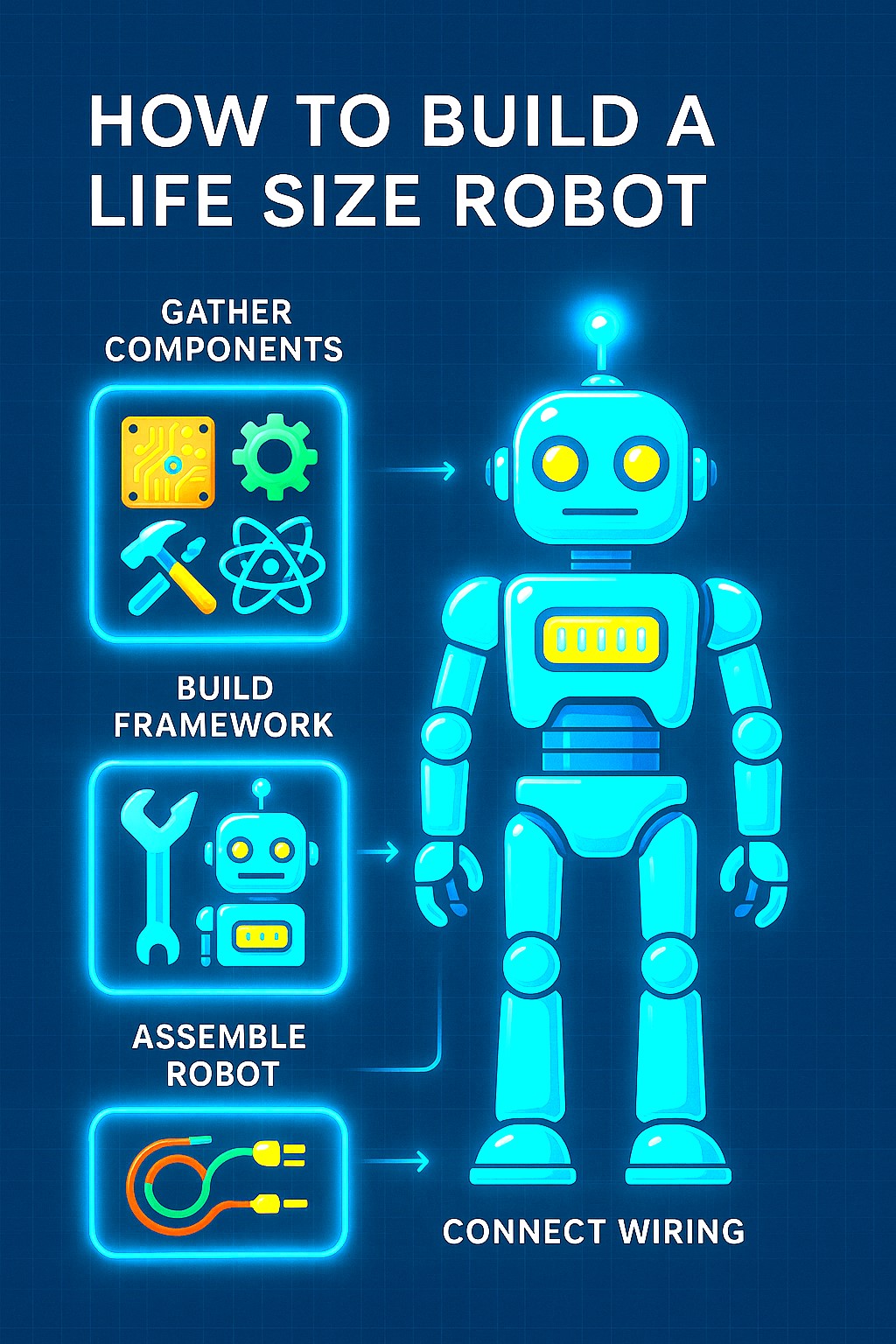

How To Build A Life Size Robot

Creating a life-size robot may seem like something out of a science fiction movie, but thanks to advancements in engineering, electronics, and open-source technology, it’s more possible than ever before. Whether you’re building a humanoid companion, a functional assistant, or a robotic experiment for a school or research project, this guide will walk you through the practical steps.

Understanding the Project Scope

Before you start building a life-size robot, it’s important to define what “life-size” means for your goals. A humanoid robot the size of an adult human will require significantly more materials, power, and balance control than a smaller model.

There are four major categories of a life-size robot:

-

Mechanical frame (structure and joints)

-

Electronic systems (sensors, motors, microcontrollers)

-

Software (programming and logic)

-

Power supply (batteries or wired source)

Step 1: Design Your Robot

Start with a detailed sketch or CAD (Computer-Aided Design) layout of the robot. Use software like Fusion 360 or TinkerCAD to draw up the mechanical layout. This should include arms, legs, joints, and any movement capabilities you plan to incorporate.

Key Design Factors:

-

Height and weight of the robot

-

Joint articulation (shoulders, elbows, knees)

-

Material strength for load-bearing

-

Space allocation for internal electronics

Step 2: Choose the Right Materials

The body of your robot needs to be lightweight yet sturdy. Common materials include:

-

Aluminum: Lightweight, durable, and ideal for frames.

-

Plywood or MDF: Useful for prototyping and easier to cut.

-

3D-printed plastic (PLA/ABS): Great for custom parts.

-

Carbon fiber (advanced use): Extremely strong and lightweight but expensive.

Select materials based on your budget, availability, and tools.

Step 3: Build the Skeleton or Frame

Using your design as a blueprint, construct the frame. This skeleton is what supports the motors, sensors, and other components. Joints can be made using rotating brackets, hinges, or servo brackets depending on the desired movement.

You’ll need tools like:

-

A power drill

-

A soldering iron

-

Wrenches and screwdrivers

-

A jigsaw or hacksaw

Reinforce stress points and ensure the frame can support the total weight of all components.

Step 4: Install Actuators and Motors

Actuators are what give your robot movement. Depending on complexity, you may use:

-

Servo motors for precise angular movement (ideal for arms and fingers)

-

Stepper motors for precise linear control (used in robotic legs)

-

DC motors for general-purpose motion

Each joint or limb must be tested for torque requirements. For example, lifting a robotic arm will need stronger servo motors at the shoulder than at the wrist.

Secure each motor properly to the frame, ensuring clear paths for movement without obstruction.

Step 5: Wiring and Electrical Setup

Connect the motors and sensors to a central controller using wires and breadboards or PCBs. Plan for:

-

Power distribution: Batteries (LiPo or lead-acid) or AC to DC converters

-

Signal wires: Connect sensors, encoders, and feedback loops

-

Motor drivers: Needed to control power to motors from your microcontroller

Label your connections clearly, use heat-shrink tubing for safety, and organize wires to prevent tangling during movement.

Step 6: Add Sensors for Intelligence

A smart robot needs sensors to interact with its environment. Common sensor types include:

-

Ultrasonic sensors for distance measurement

-

Infrared sensors for obstacle detection

-

Accelerometers and gyroscopes for balance

-

Cameras or depth sensors for vision and navigation

Install sensors securely and route their wires back to the controller or processing board.

Step 7: Select and Program the Brain

The “brain” of your robot controls everything. Popular options include:

-

Arduino boards for basic control tasks

-

Raspberry Pi for advanced processing and camera input

-

Jetson Nano or ESP32 for AI and connectivity features

Use programming languages like Python, C++, or Blockly (for beginners). Key programming tasks include:

-

Motor control via PWM signals

-

Sensor data processing

-

Movement logic (walking, rotating, gripping)

-

Safety shutoffs

If using Raspberry Pi or Jetson Nano, you can even install ROS (Robot Operating System) for managing complex robotic tasks.

Step 8: Build the Outer Shell

To give your robot a finished appearance, add an outer casing made from plastic, foam, or painted sheet metal. The outer shell also protects sensitive electronics.

Design access points for battery charging, maintenance, and airflow. Add LEDs or LCDs for visual feedback.

Step 9: Power Up and Run Tests

Once everything is assembled, run system checks:

-

Test power delivery to all motors

-

Calibrate sensors

-

Run basic movement scripts

-

Confirm wireless or remote-control functionality (if applicable)

Use an external power supply for initial testing before relying on internal batteries.

If you’re using AI features like face tracking or voice control, install packages such as OpenCV, TensorFlow Lite, or speech recognition modules.

Step 10: Refine and Improve

Building a life-size robot is an iterative process. After initial testing, identify areas for improvement:

-

Upgrade motors for smoother movement

-

Improve balance with gyroscopes

-

Enhance programming with machine learning models

-

Add remote control or Wi-Fi/Bluetooth interface

Continually document your adjustments and performance to fine-tune future designs.

Legal and Safety Considerations

Before operating your life-size robot in public, check local regulations. Some countries require registration for autonomous machines, especially those with cameras or remote control capability.

Follow these safety practices:

-

Never leave the robot powered on unattended

-

Add emergency stop buttons

-

Use low-voltage systems where possible

-

Secure moving parts to avoid injury

Safety is paramount, especially when dealing with high-power motors or sharp structural parts.

Real-Life Examples of Life-Size Robots

-

OpenAI’s Robotic Hand: Though not full-body, it demonstrates dexterous manipulation using machine learning.

-

Boston Dynamics Atlas: A bipedal humanoid robot that performs parkour. Highly advanced, powered by hydraulics.

-

InMoov Project: An open-source, life-size humanoid robot that anyone can build using 3D-printed parts and off-the-shelf components.

These projects provide free access to schematics, code, and community forums for learning.

Final Thoughts

Building a life-size robot is challenging but highly rewarding. It requires multidisciplinary knowledge in mechanical engineering, electronics, and software. With time, patience, and a methodical approach, you can create a functioning robot that walks, sees, senses, and even interacts.

Whether your goal is research, education, or just an ambitious hobby, this guide is your blueprint to getting started on the fascinating journey of robotic creation.

Key Takeaways

-

Define the purpose and design of your robot before building.

-

Choose strong yet lightweight materials like aluminum or 3D-printed plastic.

-

Use servo and stepper motors for articulated movement.

-

Equip your robot with sensors and a reliable control board.

-

Ensure all wiring is safe, organized, and labeled.

-

Program using Python, C++, or ROS depending on complexity.

-

Test extensively and refine as you go.

-

Stay safe and adhere to local laws.

By following this structured approach, you can confidently bring your life-size robotic vision to life.

References

https://en.wikipedia.org/wiki/Robotics

https://en.wikipedia.org/wiki/Robotics_engineering

Links License – https://en.wikipedia.org/wiki/Wikipedia:Text_of_the_Creative_Commons_Attribution-ShareAlike_4.0_International_License

Dear Friends, welcome You to visit link below for more tech content. Thanks For Your Kind Support.

https://techsavvo.com/category/blog/