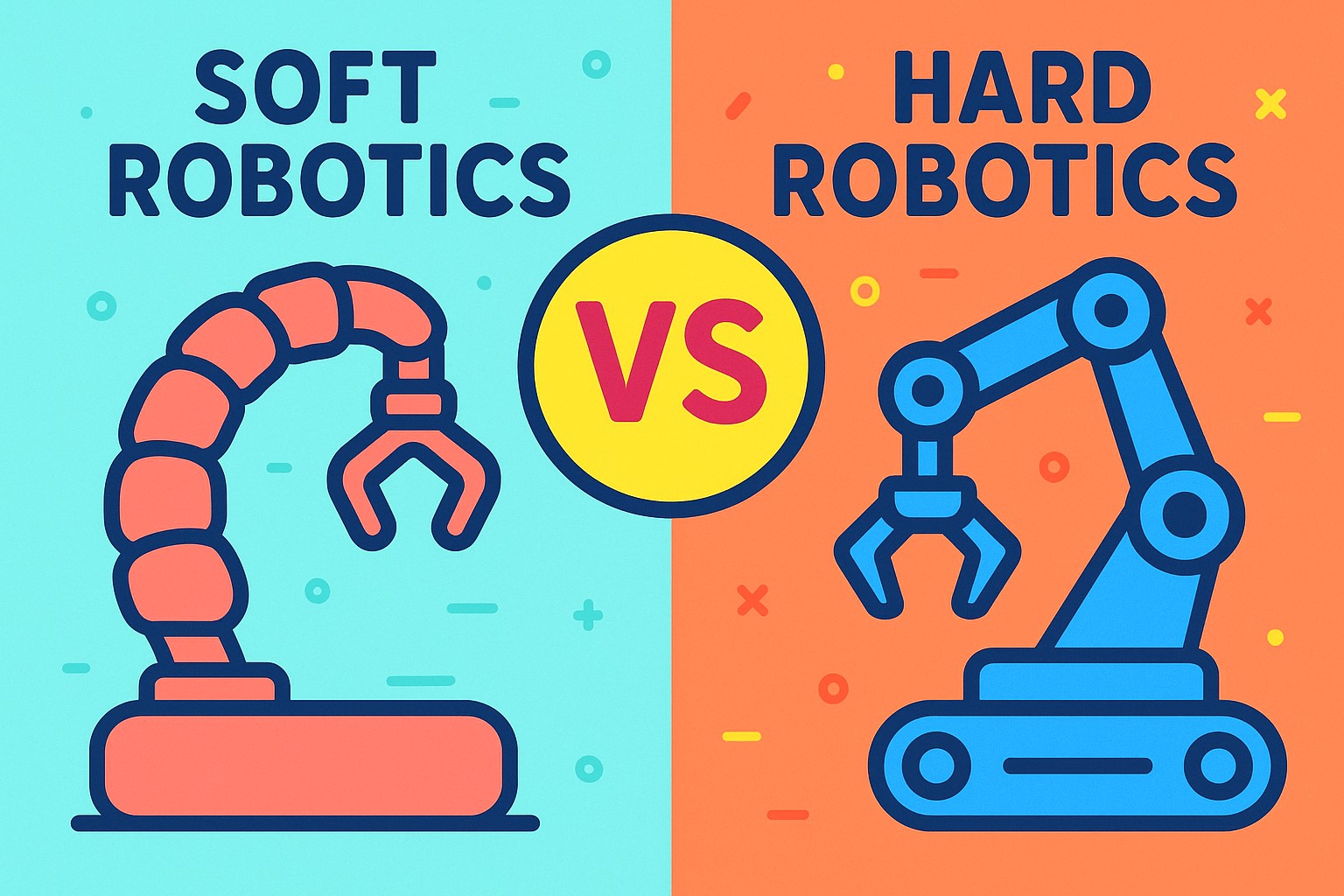

Soft Robotics vs Hard Robotics

In the evolving field of robotics, two distinct branches have emerged—soft robotics and hard robotics. These two disciplines differ not only in materials and mechanics but also in the way they interact with the environment and perform tasks. This article dives deep into the differences between soft robotics and hard robotics, highlighting their unique advantages, limitations, and real-world applications.

What Are Soft Robotics?

Soft robotics refers to the design and construction of robots using highly flexible and elastic materials, often inspired by biological organisms. Unlike traditional robots made of metal or rigid plastics, soft robots are built from silicone, rubber, or fabric materials that allow them to bend, stretch, and twist.

This flexibility makes soft robots especially suited for delicate tasks or navigating through tight, complex environments. They are often used in medical devices, rehabilitation, wearable technologies, and environments where human-robot interaction is essential.

Key Features of Soft Robotics:

-

Material Composition: Made from compliant materials like silicone, hydrogels, and elastomers.

-

Movement: Mimics organic, muscle-like motion rather than mechanical hinges.

-

Design: Inspired by soft-bodied creatures like octopuses, worms, and jellyfish.

-

Safety: Ideal for interacting with humans due to low risk of injury.

-

Control Systems: Often rely on fluidic or pneumatic actuation instead of electric motors.

What Are Hard Robotics?

Hard robotics refers to traditional robotic systems built with rigid, durable materials such as metals and hard plastics. These robots are typically characterized by precise movements, strong structural frames, and high durability.

They dominate in manufacturing, space exploration, military applications, and any environment that requires strength, speed, and precision.

Key Features of Hard Robotics:

-

Material Composition: Constructed with metal alloys, hard plastics, and carbon fiber composites.

-

Movement: Uses gears, actuators, and servo motors for high precision.

-

Design: Angular, rigid, and often bulky, designed for stability and endurance.

-

Power: Operates with electronic, hydraulic, or pneumatic actuators.

-

Application: Common in assembly lines, automotive industry, and industrial automation.

Major Differences Between Soft and Hard Robotics

Understanding the difference between soft robotics and hard robotics is essential for choosing the right solution for specific applications. Below is a comparison based on several crucial criteria:

1. Flexibility vs Rigidity

Soft robots offer unparalleled flexibility. They can deform and adapt their shape to fit through tight spaces or grasp irregular objects. Hard robots, on the other hand, are rigid and designed for high precision but lack adaptability in unpredictable environments.

2. Safety in Human Interaction

Soft robots are significantly safer for close human interaction. Their pliable design ensures that accidental contact won’t cause harm. Hard robots, though faster and more powerful, require safety barriers or controlled environments to prevent injuries.

3. Durability and Load Capacity

Hard robots are built for strength and endurance. They can lift heavy objects, perform repetitive tasks without degradation, and endure harsh conditions. Soft robots are more prone to wear and tear and are typically not suited for heavy-duty tasks.

4. Control and Programming Complexity

Soft robotics often involves nonlinear behaviors, making their control systems more complex and less predictable. In contrast, hard robotics systems are easier to model, simulate, and program due to their predictable mechanical responses.

5. Cost and Maintenance

The cost of soft robots can be lower in terms of materials but higher in terms of specialized control systems and actuators. Hard robots may require a larger upfront investment, but their robust design often translates into lower maintenance over time.

Applications of Soft Robotics

Soft robotics is gaining traction in several innovative fields due to its adaptability and safety features.

1. Medical and Surgical Tools

Soft robotic devices are used in minimally invasive surgeries where flexibility is required to navigate around sensitive organs. They are also used in prosthetics and rehabilitation to mimic natural limb movements.

2. Wearable Assistive Devices

Soft exosuits are being developed to assist individuals with mobility impairments. These suits offer support while allowing a full range of motion.

3. Agricultural Robotics

In farming, soft robots are used to gently pick fruits and vegetables without damaging them, something rigid grippers would struggle to do.

4. Search and Rescue Missions

Due to their ability to maneuver through confined or collapsed spaces, soft robots are valuable tools for locating survivors in disaster zones.

Applications of Hard Robotics

Hard robotics continues to dominate in industries where speed, precision, and endurance are non-negotiable.

1. Manufacturing and Automation

Hard robots are the backbone of automotive and electronics manufacturing, capable of performing high-speed assembly, welding, and packaging.

2. Logistics and Warehousing

Autonomous vehicles and robotic arms handle everything from sorting parcels to transporting heavy goods, streamlining the supply chain.

3. Space Exploration

Due to their durability and strength, hard robots are essential in space missions. They can operate in extreme temperatures and handle tasks like collecting rock samples or building structures on other planets.

4. Defense and Surveillance

Military robots built with hard frames can traverse rough terrains, carry heavy loads, and even perform reconnaissance missions.

When to Use Soft Robotics vs Hard Robotics

Choosing between soft robotics vs hard robotics comes down to understanding the requirements of the task at hand.

-

Choose soft robotics if the task involves interacting closely with humans, handling delicate objects, or navigating complex terrains with irregular shapes.

-

Choose hard robotics if the environment demands speed, strength, durability, and consistent precision.

Sometimes, hybrid systems are employed—where soft components are integrated with hard structures to balance strength and adaptability.

The Future of Robotics: Soft, Hard, or Hybrid?

The future of robotics lies not in choosing one over the other but in blending the best of both soft and hard robotics. Researchers are developing hybrid systems that incorporate soft actuators in rigid frames, combining the adaptability of soft materials with the precision of hard structures.

Additionally, advancements in materials science, 3D printing, and artificial intelligence are pushing both fields forward. Programmable materials, for example, are enabling soft robots to change shape autonomously based on environmental feedback.

Conclusion

The comparison between soft robotics vs hard robotics reveals two complementary paradigms. While soft robots offer flexibility, safety, and human-centered design, hard robots provide power, precision, and industrial efficiency.

Understanding the unique advantages of each helps in designing robotic systems tailored for specific tasks—whether it’s assisting a patient during rehabilitation or assembling microchips at lightning speed. As robotics continues to evolve, we can expect greater integration between these two worlds, leading to smarter, safer, and more capable machines.

ey Takeaways: Soft Robotics vs Hard Robotics

-

Definition:

-

Soft robotics uses flexible, elastic materials for gentle, adaptive tasks.

-

Hard robotics employs rigid structures for high-speed, high-precision operations.

-

-

Materials Used:

-

Soft robots are made of silicone, rubber, or hydrogels.

-

Hard robots are built with metals, plastics, and carbon composites.

-

-

Flexibility and Movement:

-

Soft robots can bend, stretch, and conform to different shapes.

-

Hard robots use rigid joints, gears, and actuators for controlled movements.

-

-

Safety and Human Interaction:

-

Soft robots are safer for direct human contact.

-

Hard robots require barriers or strict controls to avoid injury.

-

-

Application Areas:

-

Soft robots excel in healthcare, agriculture, and wearable devices.

-

Hard robots are dominant in manufacturing, logistics, and space missions.

-

-

Performance Differences:

-

Hard robots offer strength, durability, and precision.

-

Soft robots offer adaptability, safe interaction, and bio-inspired design.

-

-

Control Systems:

-

Soft robotics often requires advanced, nonlinear control algorithms.

-

Hard robotics benefits from well-established, predictable controls.

-

-

Hybrid Approach:

-

Many future systems will combine both soft and hard robotics for optimal performance.

-

-

Innovation Trend:

-

Advances in AI, materials science, and 3D printing are pushing both fields toward convergence.

-

-

Practical Decision:

-

Use soft robotics when safety, flexibility, or delicacy is key.

-

Use hard robotics when power, accuracy, or load capacity is needed.

-

References

https://en.wikipedia.org/wiki/Soft_robotics

https://en.wikipedia.org/wiki/Soft_robotics

Links License – https://en.wikipedia.org/wiki/Wikipedia:Text_of_the_Creative_Commons_Attribution-ShareAlike_4.0_International_License

Dear Friends, welcome You To visit link below for more technology articles.

https://techsavvo.com/category/blog/